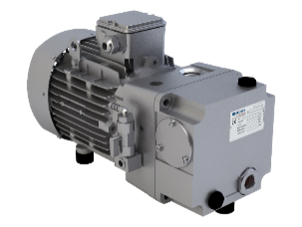

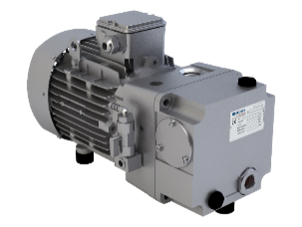

O Series 5

O Series 5

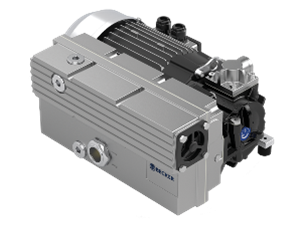

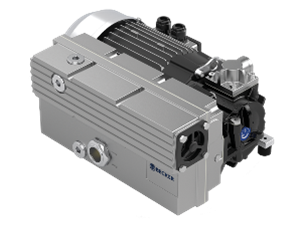

U Series 1

U Series 5

Becker’s all new “Best in Class” range of oil lubricated rotary vane vacuum pumps with 8 compact models have the fastest pump down times in direct comparison. Ultimate pressures of <0.1mbar, high efficiency IE3 motors, and MAP (O2, N2 etc.) variants available.

Each pump includes an oil filter for long oil service life, plus smooth surfaces for quick, easy and hygienic cleaning. The vacuum pump configuration with a single shaft and direct drive results in a sturdy and durable unit with low maintenance and running costs.

A non-return valve and efficient oil separation are integrated into each vacuum pump. A float valve reliably regulates the return oil intake, even in high pressure ranges. A gas ballast valve (as standard from U 5.70 and with increased volumetric flow as an option) prevents the condensation of steam as far as possible.

The gas ballast lets a measured amount of fresh air enter the compression chamber. By mixing saturated intake air with unsaturated fresh air, condensing is kept to a minimum. In addition, the protective cover supplied as standard minimises noise emissions.

An optional water cooling system allows the pump to be operated in higher ambient temperatures or with higher intake temperatures; the service life of the lubricant is also significantly increased. A wide range of accessories complements the pump, making it ideal for various tasks.

Becker packs in the most efficiency. Chances are we have higher m3/h per kW than the pumps you are using now. That’s value, because faster pump-down means higher productivity.

To download the brochure showing the sizes and technical specifications of the new Series 5 Oil Lubricated Vacuum Pumps, please click here.

Get in touch with us

LEADERS IN VACUUM PUMPS, SERVICE AND SPARES FOR COMMERCIAL& INDUSTRIAL